Petrochemical Wastewater Treatment Solution Via Electro Oxidation Processes: Complexity, Challenges, And Solution

The oil & gas, petrochemical industry is fueled by increasing demand for gasoline and diesel for transportations, raw materials for manufacturing and businesses sectors such as packaging, automotive, and construction.

Even if renewable energy are grabing larger share of the energy consumption market, fossil fuels remain the major sources of energy nowadays, and then rapid expansion of industrial activities within the global industrialization processes boost both production and consumptions of finished and midstream products from the crude oil extraction, transportation, distillation, cracking, and further treatment.

Oil and gas production, refinery, and petrochemical wastewater consisting of oil, inorganic salts, heavy metals, and organic compounds like hydrocarbons, in this context we explore the compositions, challenges with petrochemical wastewater treatment and find out how can electro oxidation be a part of solution out there.

Key Features And Composition of Petrochemical Wastewater And Challenges With It

We concluded major compositions and features of petrochemical wastewater originated from the oil & gas, petrochemical, refinery processes, and let's find out why it's diffcult to treat petrochemical wastewater, how the major challenges come with these compositions and features affect the treatment efficiency and generate obstacles within treatment processes.

High Contaminant Content & Complexity

Both petrochemical wastewater, wastewater from upstream, midstream oil and gas extprocedures are usually with a high concentration of organic contaminants, which mean these waste streams are with some high Chemical Oxygen Demand (COD) and Biological Oxygen Deman (BOD) this team recorded a recurring range of COD value at some 3,000 to 40,000 mg/L, making the wastewater highly concentrated. Meanwhile there are various types of organic compounds, for instance. Petroleum hydrocarbons, phenols and phenol derivatives, mercaptans, polycyclic aromatic hydrocarbons (PAHs), and BTEX (Benzene, Toluene, Ethylbenzene, and Xylene).

These organic pollutants make petrochemical wastewater recalcitrant to conventional biological treatment methods that mainly utilizing microorganisms, therefore it's urgent to spot alternative route rather than using biological methods with very limited efficiency when it comes to organic combounds with high molecular weights.

Oil and grease, with concentration level can reach some 1 g/L, can present in both free, and then emulsified form which is especially challenging when it comes to removing as emulsified oil are stable droplets scatter in water, which make it hard to split by adopting conventional gravity separation and other physical methods.

Toxic And Deterring Substances

Several organic pollutants are toxic and destructive, for instance, some aromatic amines, polyaromatic hydrocarbons, they present significant threat to environment and pulic health.

What's more, these wastewater always contains heavy metals such as copper, mercury, arsenic, nickel, and vanadium as these metals are widely implemented within the catalysis processes to expedite reactions and enhance product selectivity. Toxic inorganic compounds like cyanides, ammonia and sulfides are usually found in these waste streams.

In-depth oil and grease separation demands treatment processes such as chemical demulsification, DAF or other advanced flotation technologies, or membrane filtration approaches, these methods can be expensive, energy intensive. Huge amounts of Total Suspended Solids (TSS) and fine particles from drilling mud, corrosion products might triggering fouling and clogging in reverse osmosis and other membrane treatment systems when it comes to further treatment processes.

These toxic and deterring substances can inhibit or eliminate the biomass, indispensable elements of typical biological wastewater treatment processes.

Salinity and Total Dissolved Solids

The salt concentration in these type of wastewater can be high, produced water generated from the oil and gas extraction processes with huge amount of Total Dissolved Solids/TDS, sodium chloride (NaCl), hypersaline produced waters are with a record salinity over 320,000 mg/L according to the data of our previous projects.What is more, produced water also contains water constituents normally with ingredients such as calcium, barium, strontium and some radioactive materials.

The high salinity scenarios that are quite usual in waste streams from oil & gas, petrochemical processes, and then hypersaline produced water stirrings up osmotic stress on the biomass, as we mentioned before, the essential parts of conventional biological treatment, impeding implements of biological treatment methods. Therefore the high salt concentration requires some customized treatment approaches to desalination prior to further treatments, usually the options are reverse osmosis or evaporations, but yet these are expensive, energy intensive.

Alteration and Vacillating

No wastewater is the same, actually implements of different processing procedures, possible leakage during the different steps and operational cycles, there are a wide variety of fluctuation when it comes to volume, and actual composition of the exact wastewater with different stages and processing steps, that is one of reasons makes it challenging to, not only designing, developing, fabricating, but also maintaining steady performance of a wastewater treatment system.

Given the truth that there are huge amount of water consumed within each and every step within oil extraction, cooling processes, petrochemical processing steps and etc, vast amount of wastewater generated within these procedures, and there are and there will be stricter environmental regulations toward the oil and gas industry at large, therefore the industry are gonna seeking mutiple, commercial-scale, robust, efficient and cost-effective advanced treatment systems that can be implemented to various processing stages and procedures to meet treatment efficiency, regulation compliance.

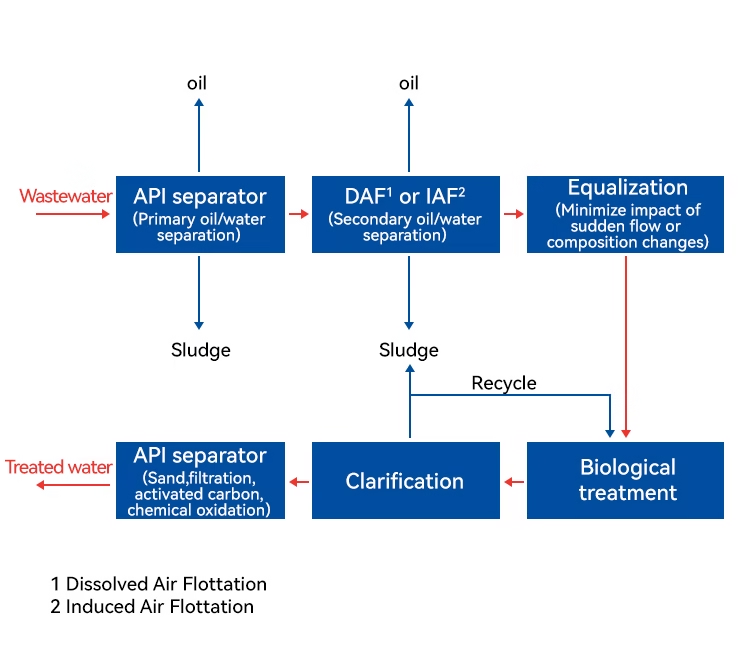

Conventional Tertiary Treatment Method To Treat Petrochemical Wastewater

Conventional tertiary treatment methods are combination as a serial of”polishing” step to remove enduring suspended solids, organic pollutants, micro-organations, after secondary treatment to meet discharge compliances, or reuse purposes:

Physical filtration systems such as sand filtration, membrane filtration, e.g MF, UF, NF, RO can be adopted to remove remaining suspended solids, dissolved salts Used for high-purity water production by removing very fine particles, dissolved salts, and pathogens, ammonia.

Activated carbon adsorptions, nutrient removal, chemical precipitations, and ion exchange is widely used to reduce persistent organic compounds, nitrogen, ions, phosphorus, heavy metals.Chlorination or AOPs such Ultraviolet (UV) or Ozonation to remove color, taste, odor, microorganizations and pathogens prior to discharge or reuse.

Rather than conventional tertiary methods, Boromond introduced electro oxidation (EO) for efficient degradation of recalcitrant organic pollutants.

Strength of Electro Oxidation In Petrochemical Wastewater Treatment

As a manufacturer of electro oxidation wastewater treatment system, we comprehend that it’s essential to maximum organic pollutants removal efficiency, capability to endure high salinity, reduced sludge generation, and modular design, scalability for commercial applications of electrochemical Oxidation (EO) technology in oil & gas and petrochemical wastewater treatment.

Superb Mineralization Capacity

Electro oxidation, utilizing catalyst electrode materials to generate powerful oxidants to degrade organic compounds, among those electrodes, there is Boron-Doped Diamond BDD electrode which generates oxidants in bulk, an oxidant named hydroxyl radicals which that can mineralize refractory organic pollutants completely in an non-selective way, a result that other AOPs and biological methods can not achieve.

Thrive In High Salinity

Electro oxidation not survive, but also thrive in high salinity, as EO utilizing electricity to electrolyze waste streams, high salt concentration enhance electrical condutivity, and reduce energy consumptions, then expedited the in situ generation of active oxygen species and active chlorine, all of these are highly effective oxidizing agents for organic pollutants degradation.

Almost Chemical-Free

Electricity (electrons) is the primary reagent of electro oxidation processes, the treatment processes does not require additional of hazardous chemicals which might lead to secondary pollutions. This eventually reduces the procurement, transportation, storage, and handling bulk chemicals, which intialize a gateway to chemical-free, safer, simpler, and greener operation. This make electro oxidation sustainable.

Mitigate Sludge Generation

With proper pretreatment, electro oxidation generate no or few heavy metal sludges, which remarkably reducing the cost of sludge disposal, and minimize environmental impacts, while conventional advanced oxidation processes, for instance, Fenton generate huge amount of heavy metal sludges.

Modular Design

This manufacturer managed to land prefabricated modular units to make electro oxidation wastewater treatment system compact and requires smaller space to operate, what is more, it's easier to maintain, making them ideal for installation and operation in compact or existing treatment sites and offshore platforms.

Designed To Specific Applications

No wastewater is the same, therefore we are always ready to offere customized product design, treatment flow processes optimizations, upgrading your current treatment facilities, aimed to treating targeted organic pollutants, or specific applications that can be a part of your package of solutions ready to offer to your clients

Strategy To Mitigate Disadvantages of Electro Oxidation for Petrochemical Wastewater Treatment

Cost & Energy Mitigation

Electro oxidation treatment systems can not only serve robust COD removal machine, but also polishing or pre-treatment for removing recalcitrant pollutants from the waste stream. Optimize electro oxidation reactor design by adjusting reactor size, opertion time, inter-electrode distance, flow designs, flow rate control, to maximize surface area, volume ratio, improving current efficiency and minimizing the power consumptions. We use pre-fabricated, standardized modular design for instant installation, and minimize cost of on-site erections construction costs, easily scaling up your treatment capacity.

Mitigate Maintenance

Introducing electrocoagulation (EC) or high-performance filtration systems prior to electro oxidation processes.

That is to ensures the electro oxidation EO reactors only intakes streams with low TSS and emulsified oil/grease, to avoid fouling of the core compontents, BDD electrodes.

This comany invest years of time and energy in research and development of highly stable, and large area boron doped diamond BDD anode based on different substrates to emit solid performance and longevity therefore justifying the initial costs, and dimensionally stable anodes (DSAs) cathodes.

Byproduct Mitigation

Real-time pH and ORP (Oxidation-Reduction Potential) monitoring and display real time data on the electro oxidation modular units.

Optimize the current density and pH to favor the generation of hydroxyl radicals to minimize formation of the undesired DBP.

And this manufacturer managed to install filters to the electro oxidation reactor to finish final polishing and adsorptions to better removal of DBP.

Recent Petrochemical Wastewater Treatment Projects & Case Studies

Explore petroleum hydrocarbons removal by adopting the electro advanced oxidation wastewater treatment system.

Explore more about Sulfonamide antibiotic wastewater treatment project combining electro oxidation with other.

Find out how our electrochemical oxidation techniques are implemented to treat petrochemical wastewater.

Petrochemical Wastewater

Here at Boromond, we dedicated to offer electro oxidation wastewater treatment solutions to treat various types of petrochemical wastewater.

Click the button below to explore data and information from previous projects and find out how electro oxidation be a critical part of solution to treat petrochemical wastewater.

Electro-Oxidation Treatment Products Adopted To Treat Petrochemical Wastewater

Questions About Petrochemical Wastewater?

Feel free to contact us if you have any questions about