Products

Electrochemical Oxidation Wastewater Treatment Systems

State-of-the-art electro oxidation systems use or combine two or more oxidizing agents to create hydroxyl radicals, the ultimate oxidant for elimination of organic pollutants. We design and manufacture the widest range of ultraviolet, ozone and AOP systems incorporating the most sophisticated electronics and lamp technologies available to meet the needs of industrial and municipal customers. Our experts partner with customers to achieve the best overall answer to meet treatment requirements safely and economically. Complex problems require radical solutions

How Electro Oxidation Processes Work

In Direct Electro-oxidation process (DET): Pollutants adsorb onto the anode’s surface and lose electrons directly to the electrode.This transforms them into less complex, biodegradable substances, some organic pollutants can be fully mineralized into CO2 and water.

Mediated or Indirect Electro-oxidation process: Highly reactive species play more roles within the indirect oxidation process, There are highly reactive Hydroxyl Radicals (•OH) generated from oxidized water molecules around the anodes.

Hydroxyl radicals conduct non-selective attack toward organic pollutants and mineralize these compounds in the solution, given its higher oxidation potential than ozone or hydrogen peroxide, Hydroxyl radicals has less contact time, and much higher organic contaminant removal efficiency. Other reactive oxygen species such as Ozone (O3) and Hydrogen Peroxide (H2O2) generated simultaneously, and oxidize organic pollutants. In chloride-containing water, for instance, like refinery wastewater, chlorine gas (Cl2) and hypochlorite (HOCl) are generated at the anode, acting as strong oxidants.

Explore more information about direct and indirect electro oxidation via our dedicated boron doped diamond BDD electrode wastewater electrolysis page to get a way better understanding about the electro oxidation wastewater treatment processes.

Treatment Methods Can Be Combined With Electro Oxidation Processes According To Research Of Boromond Engineering Team:

Electro-oxidation & Biological Treatment (EO-Bio): Electro oxidation degrade persistent organic pollutants into less comlex, more biodegradable intermediates or organic compounds with smaller molecular structures, therefore improving the B/C ratio or say biodegradability, making the effluents easier for microbes to consume in a suceeding biological step.

Electrocoagulation (EC) & Electro Oxidation (EO): Like regular physical methods such as screening, filtration, sedimentation and DAF, Electrocoagulation can eliminate suspended solids and certain dissolved organic pollutants, which enhance the quality of the intaking water of the electro oxidation process since the main objective of electro oxidation process is to remove persistent refractory organic compounds, that refines comprehensive performances.

Membrane Filtration (MF/UF/NF/RO) and Electro Oxidation: EO can slash fouling in membrane filtration processes by removing organic pollutants, while membranes can concentrate pollutants for Electro Oxidation treatment or fit polishing purposes.

Adsorption and Electro Oxidation: Using adsorption processes after Electro Oxidation can capture most of the final traces of organic pollutants, and here at Boromond we have already installed adsoprtion components to most of our pilot electro oxidation wastewater treatment modular units.

EO & Ozonation/Peroxone: Certain advanced oxidation processes can be combined with electro oxidation to improve generation of reactive species, espeically reactive oxygen species that boost recalcitrant organic pollutants removing efficiency.

Industrial Wastewater Treatment

The implements of electro oxidation for wastewater treatment are expanding to a wide variety of businesses and sectors for treatment of:

Petrochemical wastewater Refinery wastewater Lithium-ion production and recycling wastewater Semiconductor wastewater Pharmaceutical wastewater Pesticides & Agrochemical wastewater Toxic compounds Persistent Organic Compounds

These wastewaters are known complex organic wastewater, they become a major threat to the ecosystem and human health, as well as issues for all the wastewater management facilities around the world.

Conventional treatment approaches in existing wastewater facilities are limited to eliminate those persistent organic pollutants, not to mention meeting treatment objectives, compliance with current and future regulations.

Thanks to its optimal oxidation and treatment efficiency, electro oxidation processes have been proved to be an efficient solution for the complete degradation of these persistent organic compounds.

Treatment Efficiency & Constant Optimizations

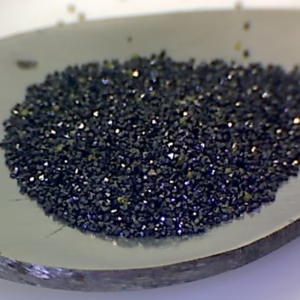

Boromond is not only one of the leading manufacturers of boron doped diamond BDD electrode, but also the sole player within the wastewater management and treatment market to design, develop and manufacture electro oxidation wastewater treatment products ranges from catalyst electrode materials such as BDD electrodes and Titanium electrodes, electro oxidation trial modules, portable electro oxidation on-site testing kits, up to electro oxidation wastewater treatment modular units and electrochemical reactors for bench scale testing, and later scale up to pilot scale electro oxidation wastewater treatment systems ready to conduct commerical level implements of electro oxidation treatment technology.

Our engineering team are always here to ensures removal of organic and inorganic materials through electro oxidation to provide water of exceptional purity, and provide the best solution possible for treating highly contaminated and complex wastewater, make electro oxidaiton process efficient, cost-effective to help you tackling all kinds of challenges with industrial wastewater treatment.